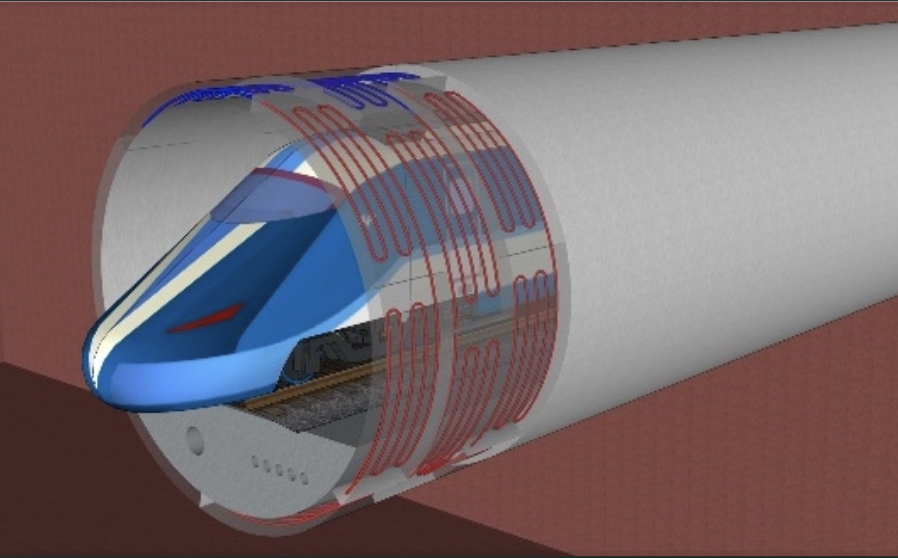

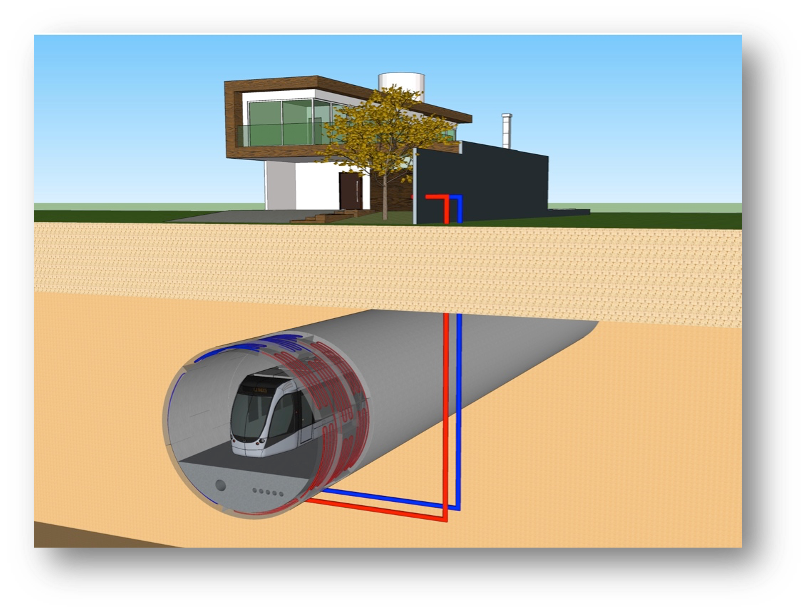

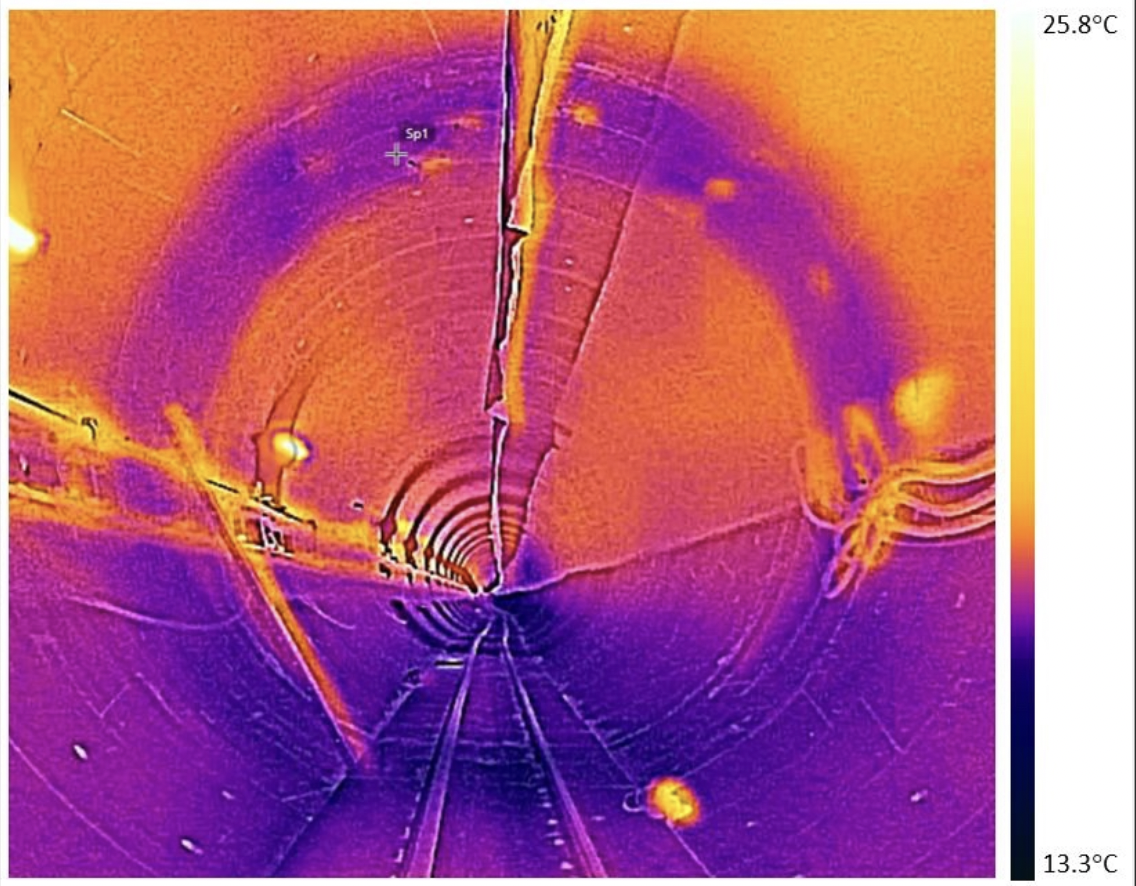

The patent is an improved tunnel precast segmental lining (ENERTUN) equipped to exchange heat with the ground to heat and cool adjacent buildings. A circuit of pipes is installed in each segment in the factory before precasting and fluid circulates through them allowing for heat exchange with the ground. The tunnel segmental lining is to be used for tunnels constructed by TBM. The concrete segment can be equipped with different configurations: a single circuit of pipes on the ground side to exchange heat with the soil (ENERTUN GROUND), a single circuit of pipes on the tunnel side to exchange heat with the tunnel internal air (ENERTUN AIR) or a double system of pipes to exchange heat with both sides (ENERTUN AIR&GROUND). Each equipped segment is connected to the adjacent one through hydraulic connections to form a ring of the segmental lining. The system allows maximising the heat exchange and reducing the hydraulic head losses. The system can be used to extract heat from the ground to heat the adjacent buildings or inject heat into the ground to provide air conditioning (metro tunnels or tunnels in urban areas) or to reduce costs of cooling deep mountain tunnels.