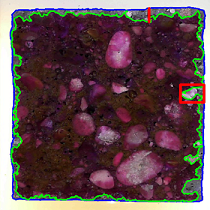

As concerns carbonation, the EN13295 standard suggests spraying a phenolphthalein solution on the target to highlight the presence of carbonated/non-carbonated areas. The phenolphthalein solution changes its colour in relation to the pH of the material: in the non-carbonated part of the specimen, where concrete has still a highly alkaline behaviour (pH > 9), a purple-red coloration is obtained, whereas in the carbonated area of the specimen (pH < 9) no colour change is observed [9]. The standard describes a procedure in which the operator is asked to manually measure the carbonation depth (dk), i.e. “the average distance, measured in mm, from the surface of the concrete or mortar where the CO2 has reduced the alkalinity of the hydrated cement to an extent such that an indicator solution based on phenolphthalein remains colourless”, by using rulers, callipers, etc.

Even if this measurement method is relatively easy to perform, it suffers from subjectivity, due to operator’s experience, colours perception, and manual ability. Hence, the measurement will be characterized by low repeatability and low reproducibility, leading to non-optimal results.

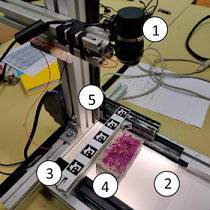

The proposed method aims at developing an automated and objective approach, based on machine vision, for measuring penetration depth of contaminants in concrete (not limiting to carbonation). Artificial intelligence is used to automatically discard aggregates that would lead to misleading results.