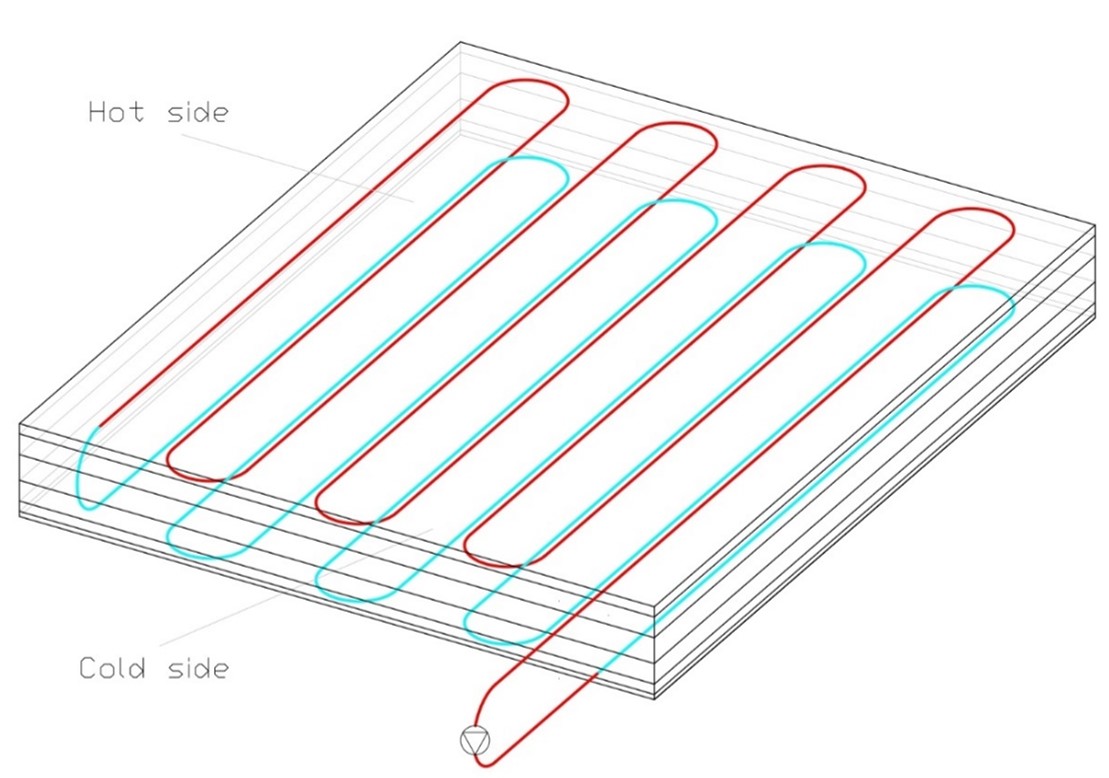

The technology is extremely simple, as it consists of a pipe crossed by a fluid (even water, but a water + glycol mixture is more suitable to avoid freezing) and a small pump connected to a control system which drives it to operate when necessary. In winter, as long as the temperature of the external wall remains lower than that of the internal, the pump is inactive, and the wall behaves in terms of thermal insulation like a classic insulating wall. When the two temperatures are inverted, i.e. when the temperature of the external wall becomes higher than the internal one for any reason (solar radiation arrival, increase in air temperature in warm climates and far from winter lows), the pump is activated to transfer heat from the outside to the inside. When the pump is running, the fluid flows in the pipe and becomes the heat carrier from the outside to the inside. In summer mode, the operating principle is exactly the same, except for the pump start mode, which is activated only when the outside wall temperature is lower than the inside one. The installation consists of laying a series of pipes at different heights in the walls and it can be performed by a plumber; the electronics are just as simple, since it is sufficient to connect the temperature probes with the pump.