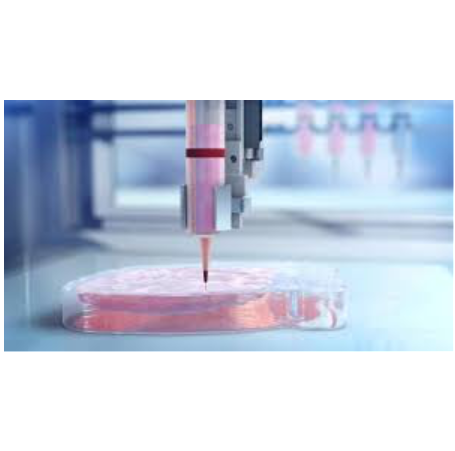

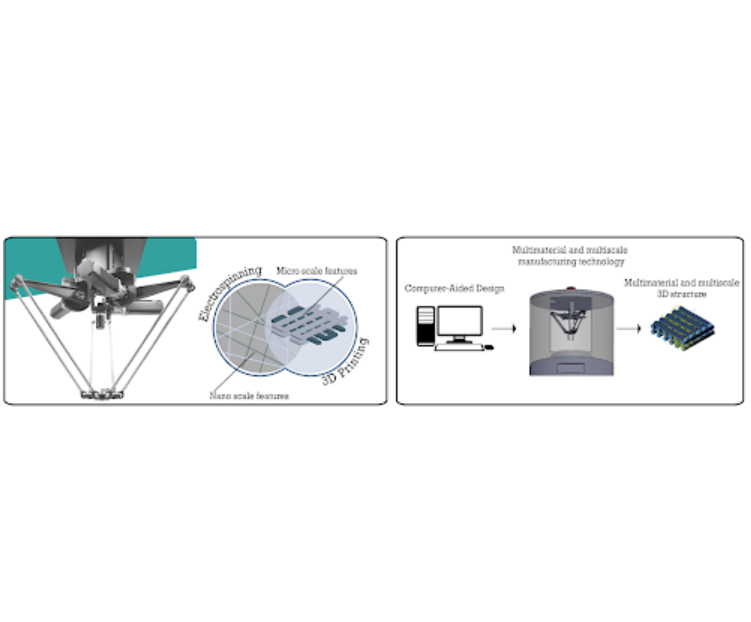

The object of the invention is a two-in-one CAD/CAM fabrication system which, by combining pneumatic extrusion (with micrometric resolution) with electrospinning (with nanometric resolution) in the same platform, revolutionizes the way to produce multi-scale and multi-material 3D structures