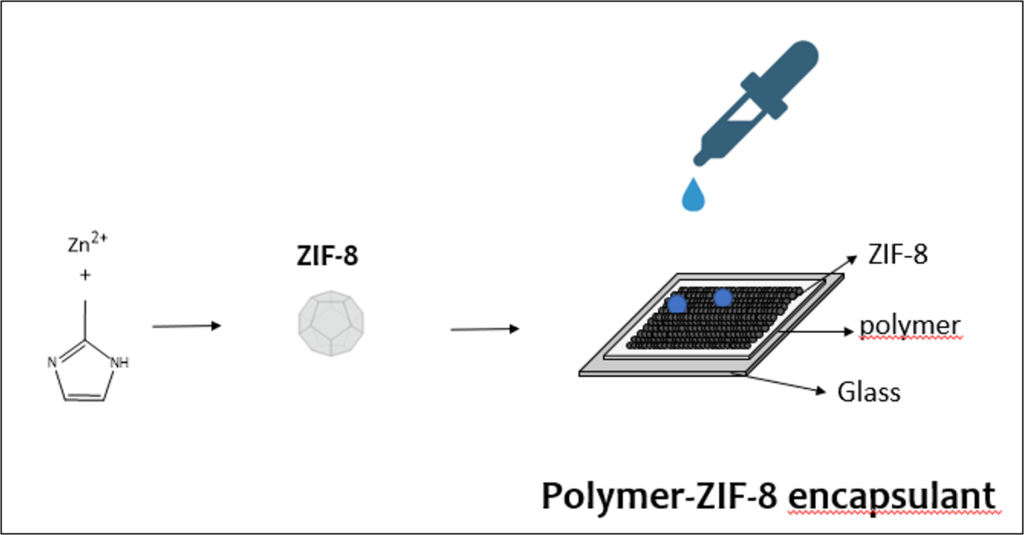

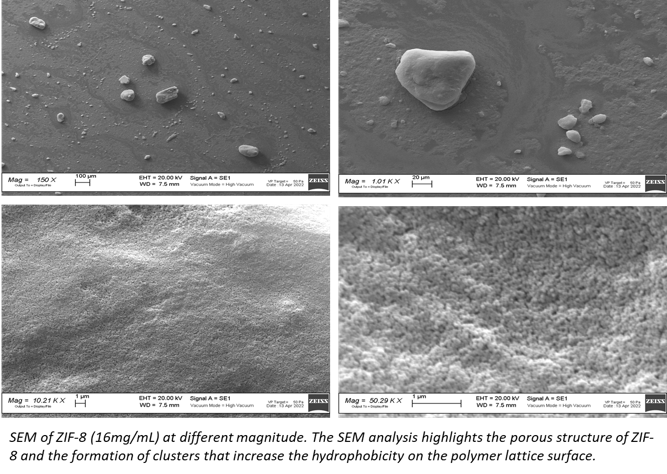

Perovskite solar cells are photovoltaic devices that aim to be the new frontier in the field of renewable energies. The efficiencies achieved (25.7%) are very close to current Silicon panels, however, their easy processability, excellent optoelectronic properties, and industrial scalability make them the most suitable technology to replace current ones. Perovskites have a crystal structure of the ABX3 type, where A is the organic cation (methylammonium, formamidinium, etc.), B is the metal cation (Pb2+), and X is the halogen. High humidity conditions promote the formation of the hydrated complex with the perovskite causing structural deformation. This results in a decay of the optoelectronic properties and ultimately the efficiency of the devices. To overcome this problem, there are various encapsulation techniques based on processes in which the device is isolated from the external environment through the use of hydrophobic polymers. However, not all devices have shown a sufficient increase in stability to make them commercially available, and the available polymers have shown issues, such as EVA, related to partial degradation following exposure to high humidity conditions.