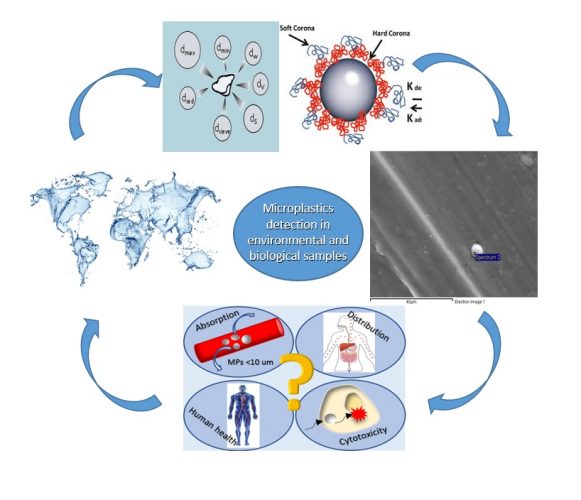

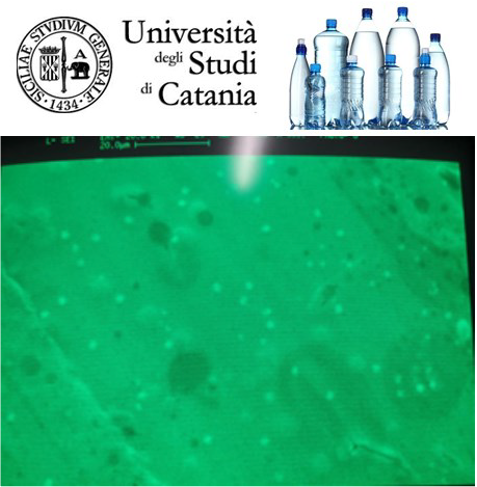

The uncontrolled introduction into the environment of plastic polymers have caused the dispersion of Microplastics (MPs). MPs represent an important issue for environmental, human health and for the innovative quality checks of commercial products according to both the legal innovations and new guideline on renewed management of plastic, which the European Community is gradually defining and applying. The invention presented allows the extraction of micro- and nanoplastics including those <10 microns in organic, inorganic, solid and liquid matrices