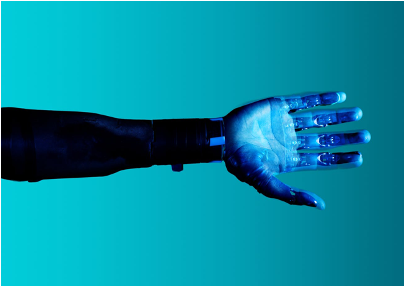

Tactile sensor emulates the human sense of touch in sensing and locating a pressure over a large surface, reproducing human mechanoreceptors activity. The current patent includes the sensor manufacturing process, a robotic arm coated by this sensor, and a method for its operation.

Innovative for its lightness and adaptability to large curved surfaces, it can cover robotic prostheses and / or collaborative robotic arms, as an artificial skin.