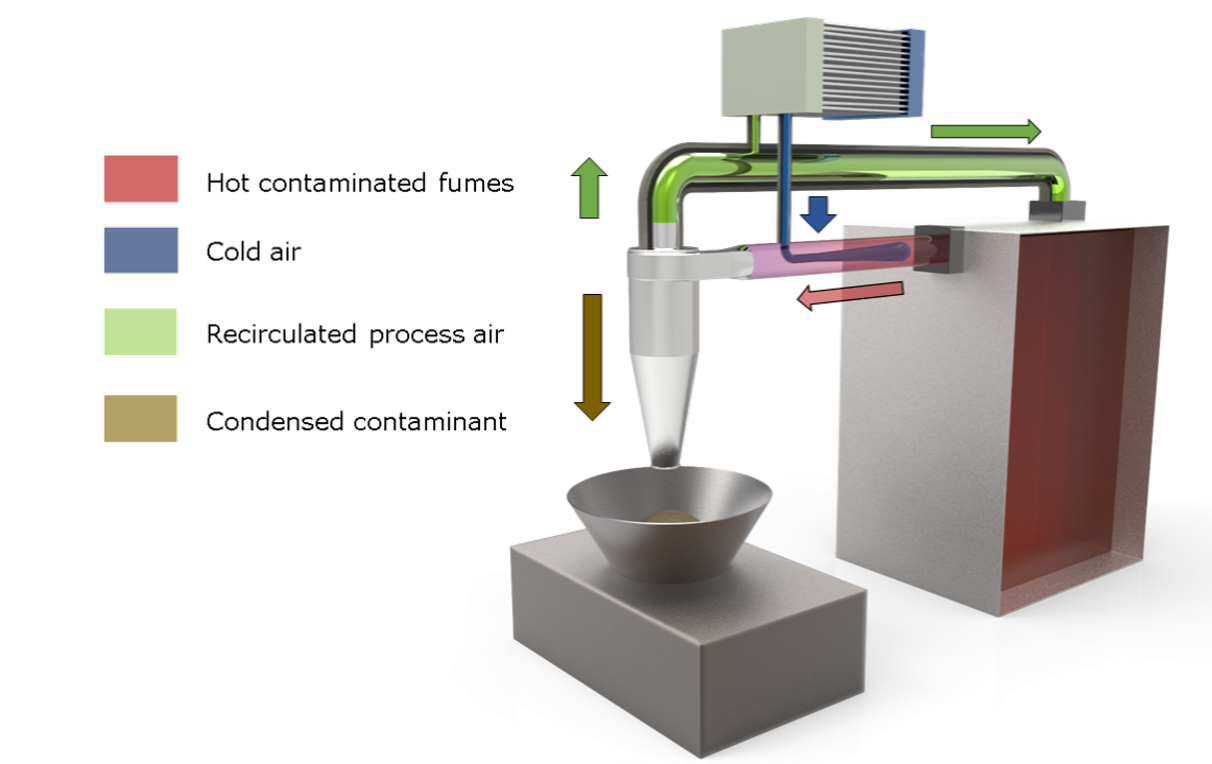

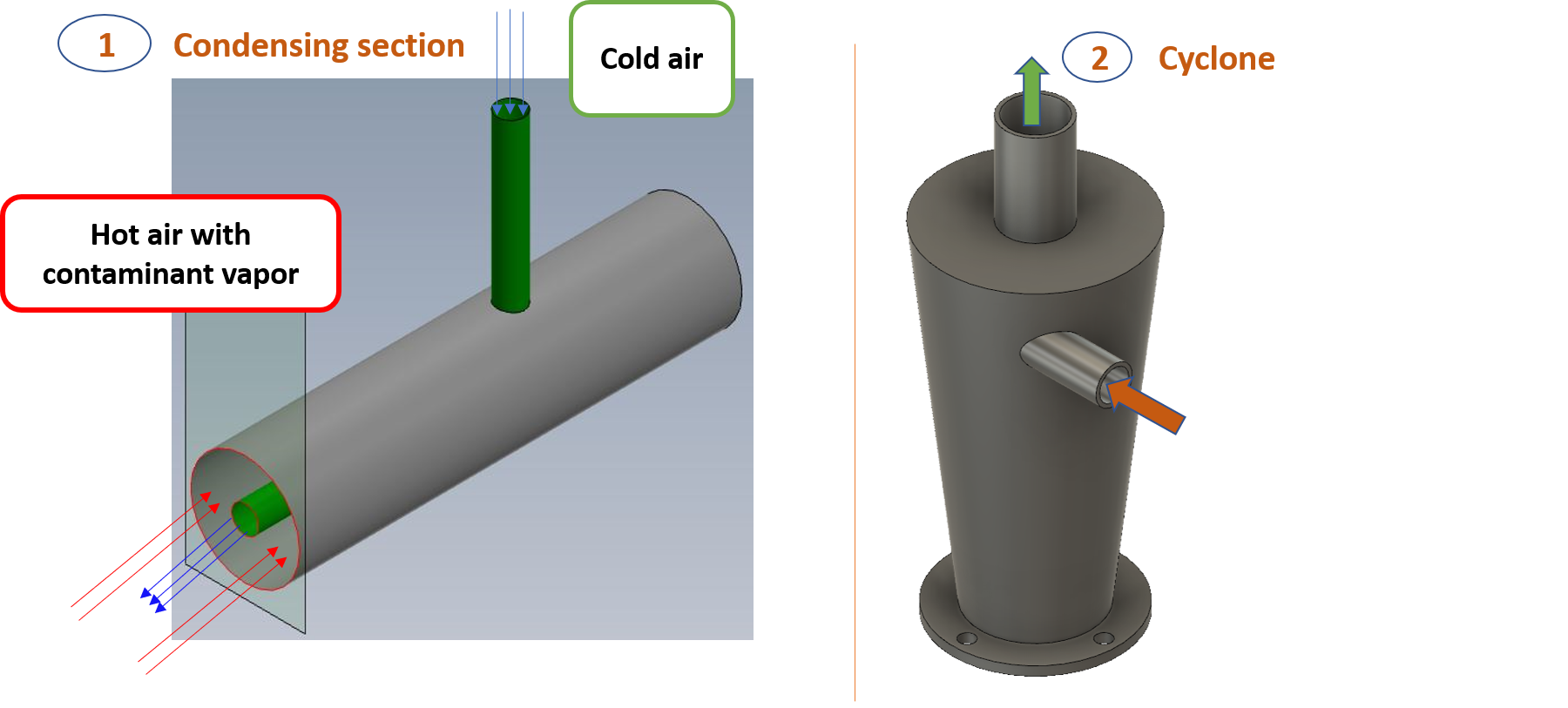

The removal of gaseous pollutants generated by industrial processes can be difficult and expensive. The inertial separator for condensed vapors (FumeCatch) is a stand-alone customized air cleaning system providing a solution for capturing condensable vapors in a more efficient way. The vapors are forced to condense in a controlled way and the droplets generated by condensation are removed by inertial devices with high efficiency and reduced maintenance.

The adoption of FumeCatch technology provides several advantages:

– Maintenance is reduced and can be automated to avoid stops in the production process

– Cleaning or regeneration of pollution control devices is reduced so that energy and water can be saved compared to traditional approaches

– Condensed vapors provide materials which can be sold on the market or reintroduced again in the production cycle