Guaranteeing the patient who has lost the limb the possibility of recovering most of the functions of a hand, while at the same time using an immediately learning, highly effective and non-invasive human machine interface (HMI), is nowadays the strongest need. in the field of prostheses.

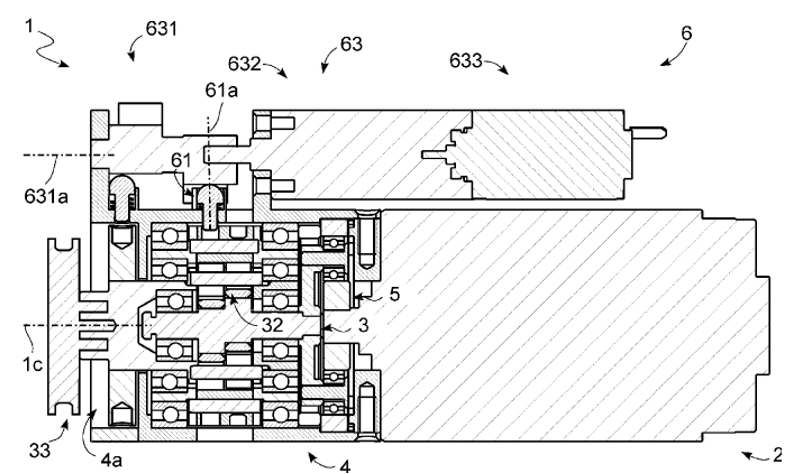

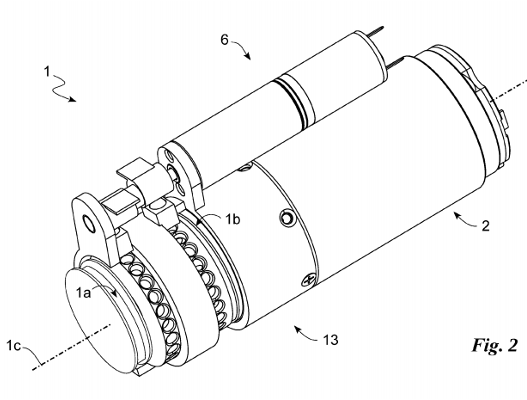

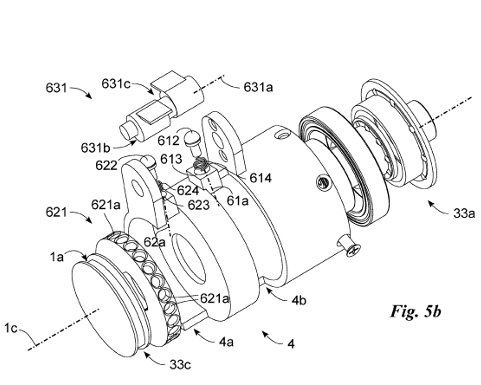

The technical problem consists in the realization of a complete hand prosthesis, which uses a single power motor to actuate both all the fingers in flexion / extension and the opposition (abduction / adduction) of the thumb, inside a hand shape. with anthropomorphic features and anthropometric dimensions. Everything has been created in order to maintain the high standards of compactness required, and at the same time guaranteeing the performance of a human hand with an activated thumb, silent in operation and irreversible with the engine off.