The proposed food product constitutes a new food product by adding value to a raw material such as olive paté (obtained from the mechanical extraction of virgin olive oil) or pomace (obtained from de-stoned olive paste). Neither products have been used industrially for food production before. Consequently, the patented product is only partially comparable to food products currently on the market, such as olive paté, which, however, use as raw material the pitted table olives previously debittered with salt concentrates of between 5% and 7%. The differences between the new product and the olive pate currently available on the market are:

- origin of the raw material;

- healthy properties: higher content of bioactive phenolic compounds, lower oil content and a reduced NaCl content in the proposed product;

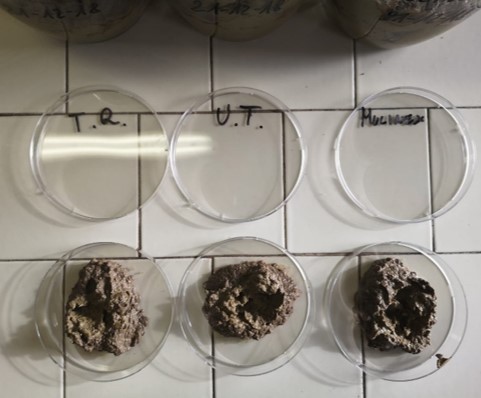

- rheological characteristics: by adding a refining phase to the olive cream manufacturing process, in which the remains of the pit and peel fragments are removed, the texture of the product is comparable to a smoot cream rather than a crushed vegetable tissue.

An unsolved problem, which is an integral part of the patent activity, is the reduction by a chemical or biological debittering process of the bitter note of the olive creams obtained from these by-products, which otherwise are not suitable for human direct consumption due to their high phenolic content.