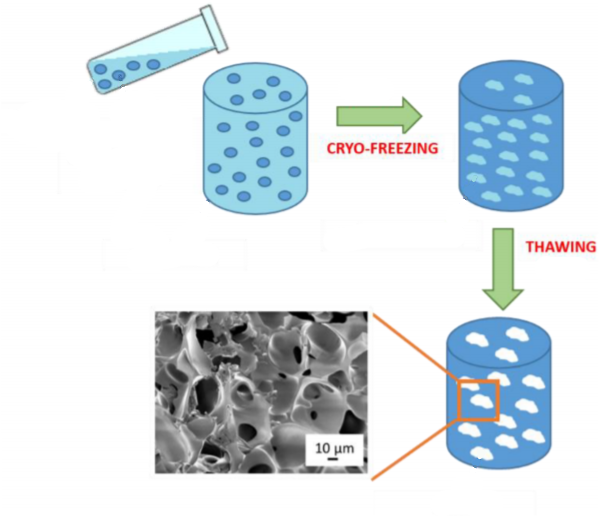

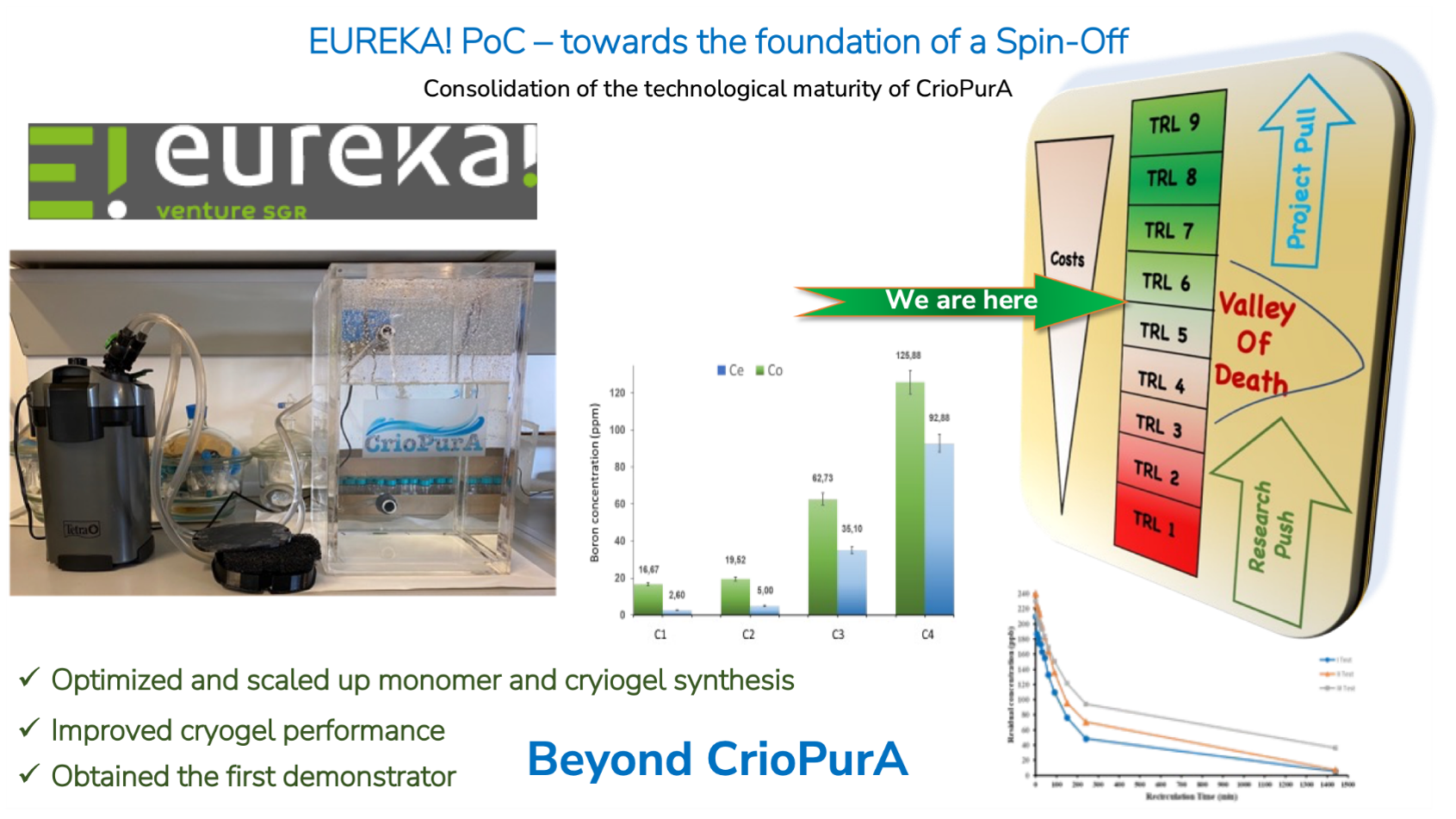

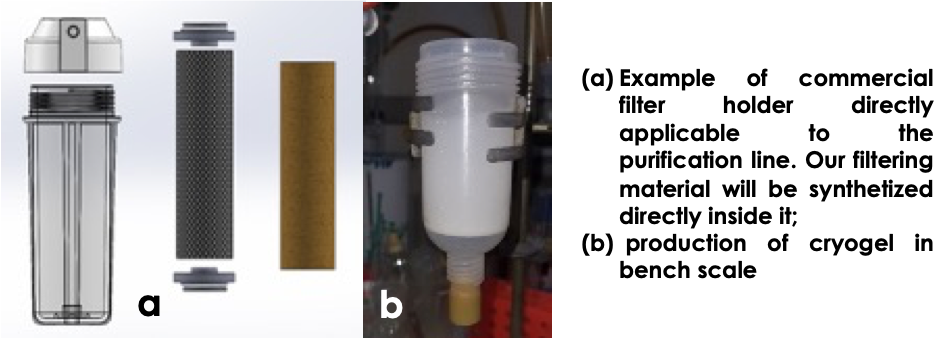

N-methyl-D-glucamine (NMG) is a chelating molecule used for environmental purposes for its high efficiency and selectivity versus metal ions species. The technology namely CrioPurA regards the realization of NMG-based hydrogels, produced by cryo-polymerization in water. The synthesis of ad-hoc functionalized polymeric materials with chelating groups is a sustainable and low-cost strategy to obtain adsorbent materials. In particular, the technique adopted for the realization of material allows to obtain different structures as well as shapes of different sizes, with high porosity, permeability and excellent sequestering action towards boron, arsenic, chromium and other metals ions from the water. CrioPurA can be regenerated, reused and adapted to existing water treatment plants.