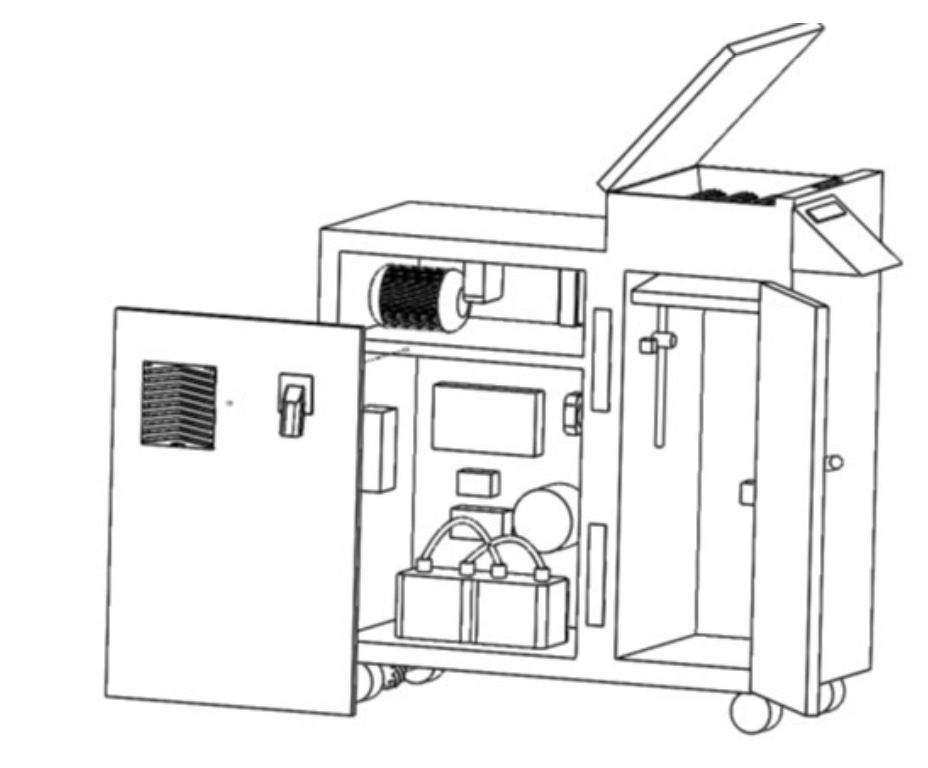

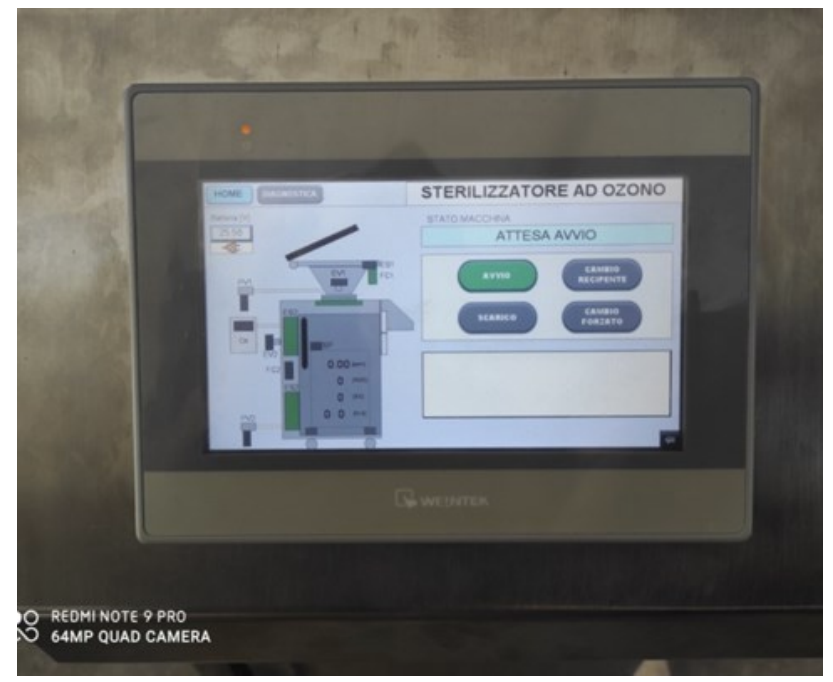

It is a mobile system that exploits the sterilizing properties of ozone, allowing, already in the context of production, the capillary collection of infectious risk medical waste and the simultaneous reduction of the microbial load. The technology makes it possible to “downgrade” the waste from special hazardous to urban and is primarily aimed at providing an effective tool for protecting healthcare workers from occupational exposure to biological risk. The reduction of the infectious risk also contributes to significantly limiting indoor biological contamination in healthcare environments, counteracting the proliferation of resistant species responsible for hospital infections, pathologies that are difficult to eradicate and constitute a real public health emergency.