This invention consists in a class of actuation systems which is specifically designed to minimize the lateral encumbrance of the exoskeletal system to maximize its practical usability.

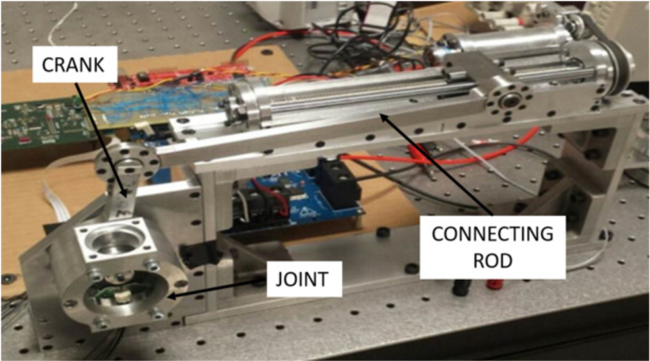

Three solutions have been developed which in which the mechatronic actuation is placed frontally instead of laterally.

The designed anti-blockage system guarantees proper functioning of each mechanical component and high backdrivability of the overall system even for high overall gearing.