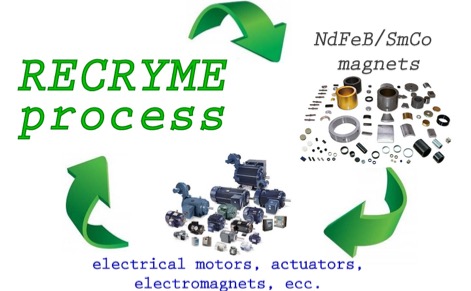

This invention consists in a process for the treatment at zero environmental impact of Wasted Electric and Electronic Equipment (WEEE) and in the recovery of ferromagnetic compounds contained in WEEE, with the needed purity grade for reintroducing them in the production cycle of permanent magnets for application to electric machines, magnetic actuators, electromagnets, sensors, etc.