An effective, sustainable, and cheap solution to safety and security problems in transports, industries, environment, and smart cities is represented by Internet of Things (IoT) devices and Wireless Sensor Networks. As an example, a condition monitoring through a Wireless Sensor Network could have prevented the well-known Viareggio disaster in 2009. Which is the energy supply of IoT devices?

- A wired energy supply, typically, is not present or not economically convenient for such applications.

- Disposable batteries have high maintenance costs (about 1.000/3.500€ in 10 years), environmental impact and low reliability.

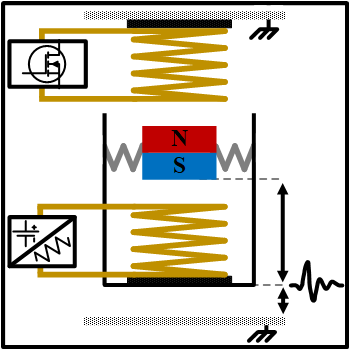

The alternative solution is the energy harvesting, the conversion into electricity of otherwise wasted energy (a harvester cost, which does not need maintenance is about 200/500 €). The main problem of energy harvesters is that their use is strongly limited by the low electrical power they can generate. Moreover, in vibration energy harvesting applications the most used harvesting technologies are strongly resonant with very limited performance when the vibration frequency is different from their mechanical resonance frequency.

The proposed invention is aimed at increasing the power generated by energy harvesting systems, especially far from their resonance, and can, therefore, significantly expand their areas and possibilities of use.